30 March 2017

Knurling Small Workpiece Diameters!

A cylinder pin (Ø 1,5 mm) made of acid-fast, stainless steel (1.4305) requires a centered RAA profile. Due to the small diameter, the pressure exerted during the forming process should be reduced to a minimum. Furthermore, the machine tool space is limited, a further application restriction that needs to be taken into account.

Application requirements:

Cylinder pin: Ø 1,5 mm

Field of application: Measuring and control technology

Material: 1.4305 Acid-free stainless steel,

HB230, Rm 625

Machine: Star SR10J

Application optimization: zeus RD2-161

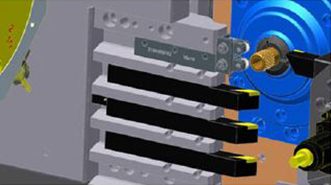

For such small work pieces, and a knurling profile on the ork piece center without a groove, the zeus knurling tool series 161 is the most suitable tool choice.

The zeus product line 161 has been developed for use in swiss type autolathes and machines with limited machine spaces. With its special tool design - two knurl holders working in axial tool direction- a very gentle processing is possible. The lateral pressure exerted on the work piece and machine is reduced to a minimum and hence work pieces from 1 mm can be knurled with high process stability.

The cylindrical pin in this application was knurled with a zeus knurling tool No. 161-08R 100404-A1 with the required results.

Application parameters:

• Knurling Tool: RW 161-08R100404-A1

• Knurling wheel: No. 10 AA 10x4x4, P. 0,5, HSS

• Application: Plunge knurling

• Speed rates: Vc = 14m/min

• Feed rate: 0,02 mm/rev

• Tool life: 5.000 pcs / 750 min/knurling wheel

• Performance: 0,11 m²