16 May 2017

Polished to a high-finish!

Smooth tooth flanks prevent built-up edges: With an additional surface treatment, premature breakage of the knurling wheels’ teeth can be prevented. When processing aluminium, a special surface treatment of the knurling wheel is recommended. In the application in case, a silicon aluminium material was processed. The work piece required a face knurl with a 3,0 mm pitch. Due to the adhesive characteristics of the material, the knurling wheels’ teeth broke at an early stage.

Application optimization

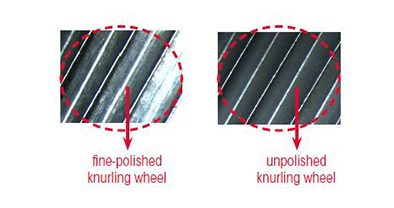

Aluminium shows adhesive bonding at the edge, resulting

in a transformation of the tool’s geometry leading to breaking of the teeth. In order to minimize this adhesive effect, smooth flanks are required. Depending on the material processed and the specific application requirements, Hommel+Keller offers a number of after-treatment services to optimize the overall knurling quality in terms of surface finish and tool life. For adhesive materials that require an optimal chipflow, fine-polished

knurling wheels have delivered an improved performance in practice. The knurling wheels are polished in-house with a special technique that allows a highly-precise rounding of the edges and excellent surface smoothing. The precise edge rounding of the tooth flanks enhances the edge stability and prevents built-up edges.

Application parameters

Application: Face knurling

Material: AlCuMgSi

Machine: INDEX ABC

Knurling Tool: 311-20R250806/13-45°

Knurling Wheel: No. 70 KAA 30x8x6/13 - fine-polished

Result

Through the use of fine-polished knurling wheels, tool life is increased substantially. Moreover, polished knurling wheels are a cost-effective alternative to ground carbide knurling wheels, that are commonly used for adhesive materials.

zeus fine-polished knurling wheels

• Smooth tooth flanks

• Precise edge rounding

• Increased tool life

• Excellent surface quality